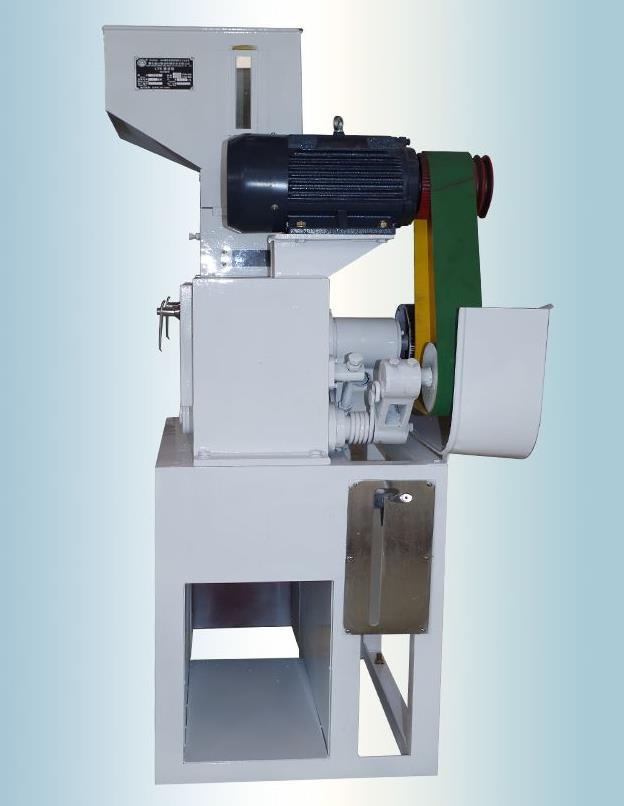

Low cost paddy thresher machine is featured with simple structure, easy operation and affordable spent.

Here,we’d like to give a brief intro on HDC paddy thresher machine to help you know how to use this low cost paddy thresher safely.

Paddy thresher working principle:

We use a 3kw motor and a blower in the rice thresher. The motor rotates clockwise to feed rice, while the counter clockwise rotation is mainly used for pushing out rice and troubleshooting. The fan is used to blow off the chips and slag produced in threshing.

The motor makes the cutter head and special-shaped cutter rotate to cut rice through the belt pulley, continuously variable belt pulley and synchronous toothed belt pulley, and the rotation speed of the cutter head can be increased or decreased by adjusting the steering handle when working; the other transmission line drives three groups of rollers to rotate by two-stage V-belt pulley and worm wheel.

Safe use and maintenance of rice paddy thresher:

(1) The safety operation education should be carried out for the thresher operators to make them understand the operation procedures and safety knowledge, such as tight sleeves, wearing masks and protective glasses, etc.

(2) Before using the paddy thresher, it is necessary to carefully check whether the rotating and swinging parts are flexible without collision; check whether the regulating mechanism is normal and whether the safety facilities are complete and effective; ensure that there are no impurities in the thresher, and add lubricating oil to all lubricating parts.

(3) Before the thresher is turned on, the working site shall be cleaned, and no sundries irrelevant to threshing shall be put; children are forbidden to play on the site, so as to avoid accidents.

(4) When working, the feeding should be even. The rice should be pushed directly into the roller. It is not allowed to push the rice into the roller with hands or forks or other tools. It is strictly forbidden to feed stones, sticks and other hard objects into the machine.

(5) The joint of the drive belt should be firm; it is strictly forbidden to take off and hang the belt or contact any object with the drive part when the machine is running.

(6) The transmission ratio between the selected matching power and thresher should meet the requirements, so as to avoid parts damage or fasteners loosening due to excessive rotation speed and severe vibration of thresher.

(7) Thresher can’t work continuously for a long time. Generally, if it works for about eight hours, it should be stopped for inspection, adjustment and lubrication to prevent serious friction and wear, heating and deformation.

(8) Paddy thresher is generally powered by diesel engine, so we should wear anti-inflammatory cover on exhaust pipe to prevent fire.

Share your thoughts Cancel reply

Your email address will not be published.

Comment *